Optimum temperature for passenger compartment and battery

- Power for temperature control can consume up to half of battery charge

- Heat conduction: similar to a domestic fridge

- Solution is basis for future vehicle generations

Electric cars’ limited range, especially in the winter months, has provoked a lot of discussion. Having the heating on can mean that the range of a lot of electric cars shrinks considerably. “Smart thermal management means a big step forward for electric cars,” says Dr. Rolf Bulander, member of the board of management of Robert Bosch GmbH and chairman of the Mobility Solutions business sector. In wintry urban conditions, this technology can enable an increase in range of up to 25 percent – without modifications to the battery. Bosch is now presenting its thermal management system at the IAA 2015 in Frankfurt.

In the publicly funded GaTE project (integrated thermal management in electric vehicles), Bosch, Mahle, Behr, and other companies developed the basis for optimized thermal management. In battery-driven powertrains, heating and cooling play a significantly greater role than in gasoline or diesel engines, since without a combustion engine, the vehicle does not have a generous supply of heat. For this reason, the passenger compartment is heated using a purely electrical system. The electricity it needs comes from the battery. This in turn impacts range: in winter and summer, roughly half the energy stored in the battery goes into regulating the temperature of the passenger compartment.

Moreover, in order to maintain the best possible supply of power to the electrical consumers drawing on it, the battery needs to be kept at a constant temperature of some 35 degrees Celsius – again with heat or cold generated electrically.

Heat-pump principle: like the domestic fridge

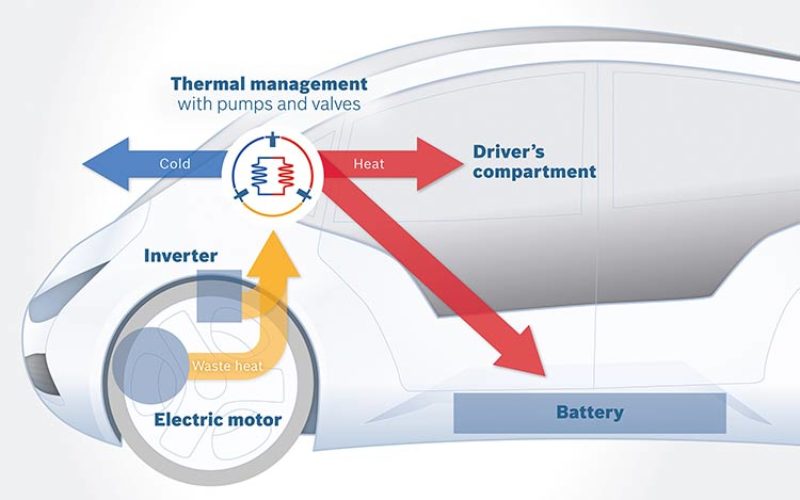

The new thermal management system distributes heat and cold solely on the basis of the vehicle’s coolant fluid. The combination of a heat pump with coolant pumps and valves makes this possible. The heat-pump principle is something everyone is familiar with in their fridges, where the heat created in the process of making the fridge cool is released into the kitchen. With the new vehicle thermal management system, a heat pump with an electrical rating of 1,000 watts will generate heat equivalent to an output of 2,000 to 3,000 watts. Conventional heaters used in hybrids and electric vehicles are only half as effective.

Bosch’s system features precisely controllable pumps and valves which collect heat and cold at source and transport them to where they are needed. The need for heating and cooling is additionally reduced by the innovative use of waste heat from the electric motor and the power electronics, plus controlled air circulation that draws moisture from the air.

System made up of already existing components

The pump makes use of the small amount of heat that is generated in an electric vehicle. For example, heat is released when supplying the electric motor with electricity. And when braking energy is converted into electricity and fed into the battery, usable heat is again created. This is also the case when the battery has to be cooled in order to remain within the optimum operating window. Most of the individual components used in this approach are already to be found in commercially available applications. Technically speaking, this innovation has the potential to bring significant and rapid improvement to electric vehicles. With its smart thermal management, Bosch is premiering a solution that will have a decisive impact on electromobility. After all, efficient temperature regulation will be a requirement for future generations of electrically powered vehicles.