- Comprehensive materials expertise forms the basis for new developments

- Cold-resistant air springs remain elastic down to -55°C

- Hi-temp air springs have a long service life, even at extreme temperatures

The temperature resistance requirements of air spring systems are becoming increasingly stringent. Extreme temperatures in particular present major challenges for developers and manufacturers. “It is only possible to develop temperature-resistant elastomer products that can withstand high temperatures above zero or icy minus temperatures with comprehensive materials expertise,” says Diethelm Bauch, head of Commercial Vehicle Original Equipment at ContiTech Air Spring Systems. “Our decades of experience in regions with extreme climates and our extensive knowledge in development set us apart. As such, we are experiencing an ever-increasing demand from commercial vehicle manufacturers for these high-tech products.”

The reason for this also lies in the growing global importance of logistics, with trucks and semi-trucks being used increasingly in regions dominated by especially hot or cold ambient temperatures. However, both extremes impose high requirements on vehicle components. Standard materials do not withstand the extreme stresses. For this reason, ContiTech Air Spring Systems has brought two new types of air spring onto the market for its customers in Commercial Vehicle Original Equipment: air springs from the Arktis series for use in especially cold areas and hi-temp air springs for use in high temperatures above zero.

Elastic at the lowest temperatures

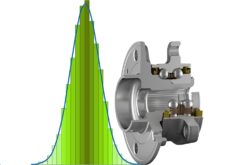

Targeting the growing transport volume in especially cold regions, ContiTech has developed a cold-resistant air spring for semi-trucks. The key basis for the cold-resistant air springs is the special rubber compound used.

“Conventional air springs lose their elasticity at low sub-zero temperatures and can develop leaks,” explains Bauch. “This is why we developed a compound and put it through rigorous testing in the cold chamber. With the new air spring, trucks are optimally equipped to operate in temperatures as low as -55°C.” Customers can identify the new air spring by the distinctive snowflake symbol, which can already be seen on Continental winter tires. The first generation has already proved successful in use in Siberia. Meanwhile, ContiTech has brought out cold-resistant variants of further air spring types.

Long service life even at 80°C

In extremely hot regions, the requirements on air springs in commercial vehicles are very different. Higher ambient temperatures and extreme atmospheric effects such as ozone and UV radiation accelerate the wear process. The installation conditions in the vehicle can further intensify this process: In particular, the proximity to the vehicle exhaust system places higher thermal stress on the air springs. Because of this, the wear of the rubber increases enormously, even in moderate climatic conditions. To slow down the process and guarantee a long service life even in high temperatures, ContiTech has developed an air spring for high-temperature applications – the hi-temp air spring. It is based on a compound comprising chloroprene rubber (CR) as the main component and is marked with the symbol of a sun. “Tests in a climate chamber have shown that the new hi-temp air spring offers twice the service life of a standard product in extreme temperatures of 80°C,” says Bauch. “This makes it the ideal solution for use under aggressive temperature influences – also outside the subtropics.”

So that it can develop and test the different requirements in practice, ContiTech operates its own laboratories worldwide as well as a certified test center in Hanover, which is able to simulate not only heat and cold but also road tests. “This reduces development times and strengthens our role as a development partner,” says Bauch. And it’s not just about extreme temperature resistance, but also about the many individual requirements of customers that are intended to make commercial vehicles safe, comfortable, and more economical.