Through the shrinking and balancing technology from HAIMER, Fendt, the corporation for agricultural machines, could increase its productivity in the metal cutting production at its plant in Marktoberdorf drastically. In the production of housings, several of the feed rates were actually doubled. Additionally, tool life increased significantly and the valuable CNC Machine Spindles were protected.

Easy handling of the HAIMER balancing machine Tool Dynamic 2009 Comfort Plus: the program takes the user step-by-step through the balancing process. The system is operated via touchscreen or by mouse and keyboard.

In 2011, when the foundation for the reconstruction of the Fendt tractor plant in Marktoberdorf and the production of cabs in Bäumenheim was laid, the goal was clearly formulated: Nothing less than the worldwide most modern, most efficient and most flexible production factory network should arise. For this purpose, the parent company AGCO invested approximately 300 million US-dollars in both locations. The design & assembly of tractors and the production of housings, among others, in Marktoberdorf were completely redesigned. The success of this measure, which was completed in autumn 2012, could be seen at the considerable interest of other industries: if you walk through the plant in Marktoberdorf, you have a good chance to meet groups of visitors from automotive manufacturers or from automotive suppliers, who are there to gather ideas for their own production. Why? “Lean Manufacturing is a frequent issue”, explains Jan-Eric Feldmann. The leader of the Housing and Frame Production at the plant points out the key data: “Slim production, shortest possible cycle times, low stock levels with correspondingly lean logistics and a high proportion of value added.” The plant especially serves as a model for the automotive industry, as Fendt doesn’t run a built-to-order production: the customers don’t buy tractors off the shelf, but configure their tractor before their order, just like buyers of an automobile do. “In our company no tractor is completely like another one” explains Werner Schober, craftsman in the production of housings.

Extremely flexible production serves as a model

Visitors are often most interested in the extremely flexible production. From the smallest tractor with 60 horse

Especially for unsymmetrical tools, balancing is important. In this case an additional weight (light grey) had to be added on the right side.

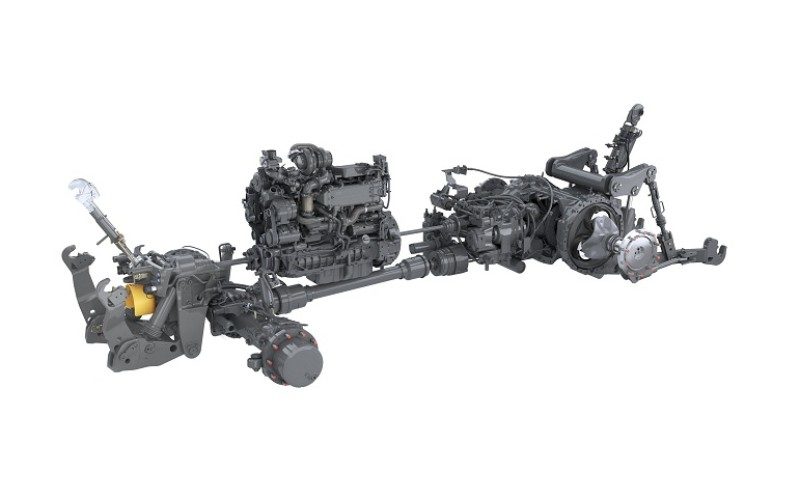

power and a weight of approximately three tons up to the biggest one with about 390 horse power and almost twelve tons, all models are assembled on the same assembly line. Approx. 18,000 units went through in 2013. One of the few commonalities: all tractors feature the continuously variable automatic transmission and four-wheel drive, developed by Fendt. Increasing efficiency and quality is an ongoing task at Fendt. Werner Schober, department head in the production of housings, started converting his tool holders to shrink fit technology from HAIMER in 2003. Already back then, the increase of efficiency by improved runout accuracy was central. In the manufacturing of tractors, the construction of housings is not only about some small components but about almost all elements, of which the bearing structure of the tractors are assembled, plus the transmission and rear axle housing. The often complex geometries of the approx. 50,000 tons of cast parts per year often require long and slim designed tools. Lengths up to 800 mm are quite common. Werner Schober invested in shrink fit chucks and shrink fit machines from HAIMER, that are easy to use and offer a very important advantage for Fendt: the possibility of internal cooling of the tools – even if extensions are used. „Due to the high feed rates, we require internal coolant to remove the chips from the bores. Before the introduction of HAIMER shrink fit technology, this was impossible“, explains Schober. Meanwhile Fendt has several thousand shrink fit chucks for drills, taps and solid carbide cutting tools in use as well as six shrink fit machines.

Higher feed rates and better surface quality

The next leap in efficiency and quality took place in 2012, after finishing the new housing production. Shrink fit chucks increase the runout accuracy per se. However, the combination of tool and tool holder results in unbalance –

A laser marks the point of the tool, where a weight has to be added or removed, in order to achieve the optimal balancing quality.

even if every single component itself has a good balancing quality. This has been annoying for Werner Schober for a long time, as he could hardly ever reach the suggested feed rates for his work piece material. In order to reach the required surface quality, he had to reduce spindle speeds and feed rates. When Oliver Lechner, sales manager at HAIMER, reported on the potential of balancing, he immediately aroused Schober’s interest. “This is because we were constantly concerned with the question of how to get faster and better” emphasizes Schober. At first, HAIMER balanced some tools of Fendt completely assembled in the tool holder as a service. The application of these tools convinced him immediately: “We could produce considerably faster and we could achieve a significantly higher quality with these balanced tools. In one case we even succeeded in raising the cutting parameters by 118 percent.” In addition to higher machining speeds, Fendt achieved further improvements. With new tools, better surface qualities can be achieved now – despite higher feed rates up to 40 percent. As in many cases, when this high quality is not required, the tools can be used for a longer time, until the quality decreases to a value that is not acceptable. So, the tool lives at Fendt were raised by 20 to 30 percent. Advantages also arise regarding the costs of machines. This is because even a very small unbalance does not only damage the tool, but also puts a strain on the valuable spindles in the CNC-machine. The direct drive high performance spindles in particular are more heavily loaded and have to be replaced earlier.

Program takes the operator through the balancing process

Before the acquisition of the respective balancing machines, only one question remained: how much effort does balancing require? Therefore HAIMER provided a machine for two months of testing, with which the Fendt

Long and slim, as well as unsymmetrical special tools are frequently in use in the production of housings at Fendt.

employees themselves optimally adjusted the tools. “This worked excellently and we decided to buy a HAIMER balancing machine” reports Werner Schober. The decision was made for a Tool Dynamic 2009 Comfort Plus, HAIMER’s high-end version with an external control terminal. In addition to technical characteristics like balancing in two planes, the easy and user-friendly handling was an important argument. The operator places the tool adapter into the balancing machine and chooses the suitable specifications from the menu. Subsequently, in a step-by-step process, the program takes the user through the balancing process. A laser marking on the tool which needs to be balanced shows where the corrections of weight through removal or addition are necessary. The required input can take place using a touchscreen or keyboard. Thus balancing can be done very quickly, even if employees haven`t worked on the machine for several days. At Fendt, balancing is not just part of the process; it is a cornerstone of the process. Normally, new tools or current tools in use that create vibrations, which indicate unbalance, are tested and balanced. Relatively frequently, special tools are also tested and balanced. “Even if a certificate states that a tool is balanced, when it is assembled into a tool holder, a significant unbalance frequently appears and that we have to correct”, explains Schober about the procedure. The needed time for measuring an unbalance and the determination of the required corrections takes only a few minutes. How long the entire balancing process takes, strongly depends on the tool. If only balancing rings have to be adjusted, the correction will be done very quickly. If material has to be removed by milling or drilling, the effort is higher. The most time is needed when additional material has to be added – but that is rarely the case.

More than 20,000 tractors and 30,000

Vario-transmissions Fendt has been producing agricultural machines for more than 80 years. The company that was founded by Xaver Fendt, produced its first “Dieselross”-tractor, with 6 horse power, in Marktoberdorf in 1930. In

1997, the globally active US agricultural corporation AGCO acquired the manufacturer of agricultural machines. Since the expansion in the years 2011 and 2012, the plant in Marktoberdorf can produce more than 20,000 tractors and 30,000 Vario-transmissions per year that are also in use in different brands of the company. In addition to Marktoberdorf, the factory network includes plants in the 120 km distant Bäumenheim (cabs and hoods), in Hohenmölsen (Saxony-Anhalt, forage harvester and heavy plate components for tractors) and Breganze (Italy, harvesters). More than 3,200 of the 4,500 employees of the factory network are employed in Marktoberdorf. Fendt uses a training center and a spare parts depot in Grasdorf together with some other brands of the network: Challenger, Fella, Massey Ferguson and Valtra.Significantly more than 90 percent of the turnover is generated in Europe; Germany is with more than 40 percent the largest single market. In 2013, AGCO generated an overall turnover of approx. 10.8 billion US-dollars.

Significant savings by an accurate runout

Unbalance produces centrifugal forces which increase exponentially with spindle speed. Assuming the same unbalance of a tool, a spindle running at 10,000 RPMs produces a centrifugal force which is 25 times higher compared to the force at a speed of 2,000 RPMs. The resulting vibrations put a strain on the spindle bearing which can reduce the spindle life time by approximately 50 percent. But the vibrations are not only detrimental for the spindle and the tool. They impair the entire process reliability and that is transferred to the machining results. They create chatter marks that have to be removed by additional finishing. Due to this it is mandatory to reduce the vibrations. The machine operator can reduce spindle speeds, feed rates and cutting depths – but at the expense of productivity. The better alternative is balancing tool and tool holder, which the HAIMER balancing machines make easy.

Courtesy: Haimer Gmbh