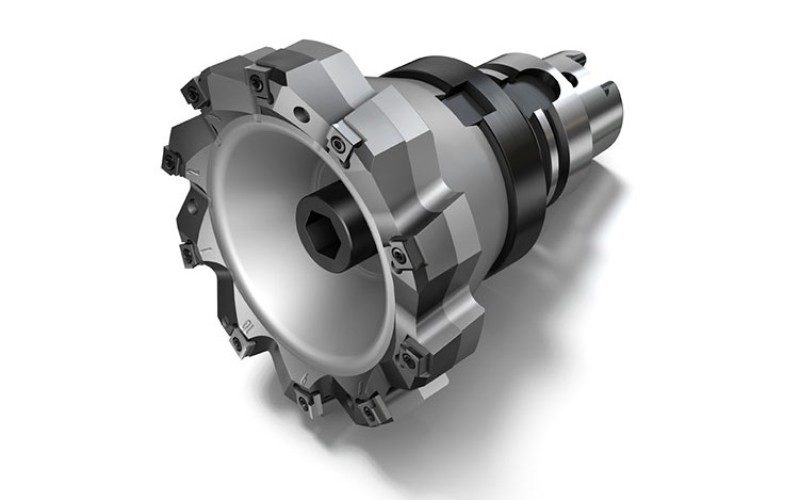

Innovative CoroMill® 5B90 milling concept from Sandvik Coromant excels at high-performance machining of aluminium components

Sandvik Coromant, a global leading supplier of cutting tools, tooling solutions and know-how to the metalworking industry, presents the innovative CoroMill® 5B90, a high-performance tool for finishing aluminium components. The state-of-the-art tool with an innovative cutting edge arrangement delivers excellent surface quality, without burr formation and reduces cost-per-part by up to 30 per cent. CoroMill 5B90 is ideally suited for typical automotive industry applications such as machining cylinder heads, gearboxes, valve blocks and motor block crankshaft and deck faces.

Numerous benefits

The new customer- and application-specific finishing cutter for aluminium allows a controlled, high-feed machining process, resulting in improved part quality. As no cost-intensive insert adjustment is necessary, set-up time can be reduced by up to 66 per cent. While each tool is custom-made for customers, Sandvik Coromant offers PCD inserts from stock.

Superior performance

When machining the cylinder heads of a four cylinder engine made from AlSi9Cu-1 at a cut depth of 0.7 mm the new CoroMill 5B90 (diameter of 160 mm, 9 cutting edges) achieved a tool life of 40,000 parts (at a rotational speed of 7,000 rev/min and a feed rate of 12,500 mm/min).