- Avails all car segments of high-end modern heating; compatible with Hands On Detection (HOD) supporting comfort, safety and automated driving

- Revolutionary product and process innovation with proprietary tooling simplifies production process

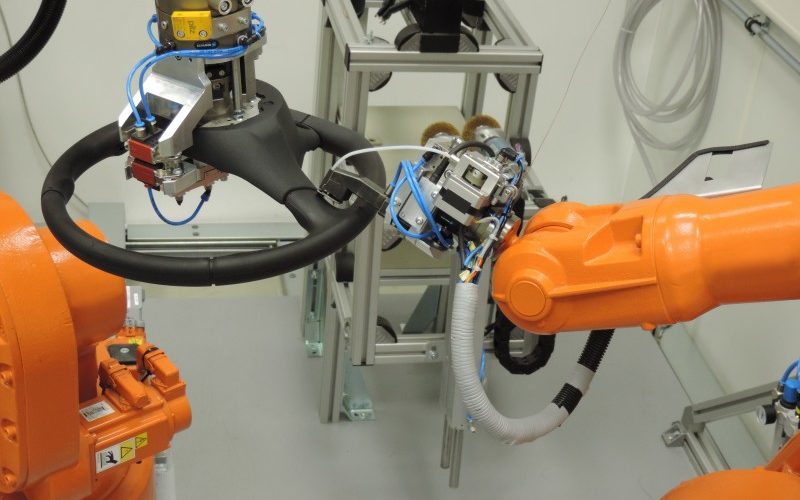

- Multi-move robot machinery replaces all manual operation with fully automated process

- Production begins in 2017 with major European VM

ZF TRW, the active and passive safety division of ZF Friedrichshafen AG, has today announced that it will start production of its innovative heated steering wheel technology (Conductor Insert Heating System, or CIHS) with a major European vehicle manufacturer in 2017. The design can be combined with ‘Hands On Detection’ (HOD) to enhance safety and comfort, and support the development of automated driving.

Bridging the gap between product design and performance; CIHS technology represents a revolutionary product and process innovation in the manufacture of heated steering wheels. Greater freedom in component design is achieved by the elimination of heat induction carrier material while product performance is enhanced by placing the heating wire directly on the steering wheel surface. These processes allow for a reduction in weight and complexity and permit the inclusion of many additional steering wheel functions, as specified by the customer.

“The steering wheel also plays a critical role in driver comfort and control as the vehicle’s primary Human Machine Interface,” Guido Hirzmann, group leader, New Technology for steering wheels. “Automated driving and the increased demand for driver assistance systems are changing the way we drive and are playing a significant role in making our roads safer. This latest ZF-TRW innovation supports this trend and can provide an important safety system (HOD) across all vehicle segments for minimal additional cost while adding the comfort advantages of a heated wheel.”

The process innovation involves the design and industrialization of several proprietary tools:

- Unique finite element simulation allows verification of the product heating performance prior to launching any process or testing activities

- Cutting and wire laying tool – to insert the conductor into the steering wheel rim in one step

- Fusing tool – fully automatic harness feeding and connection system ensuring high-quality electric connection

- Fully automatic end of line testerProduct quality is improved through simplifying the manufacturing process and using state-of-the-art, fully automatic multi-move robot machinery. Both of which were designed and developed in-house. Product qualification completion fulfilled the most stringent OEM requirements and independent OEM testing has confirmed that both product function and heating performance have been improved by up to 45 percent.