- Designed in Toulouse, ten million standardized Multi-Application Unified Sensor Elements (MUSE) have been assembled worldwide in locations in China, Korea, India, Hungary, Brazil and Mexico since the start of production in January 2014.

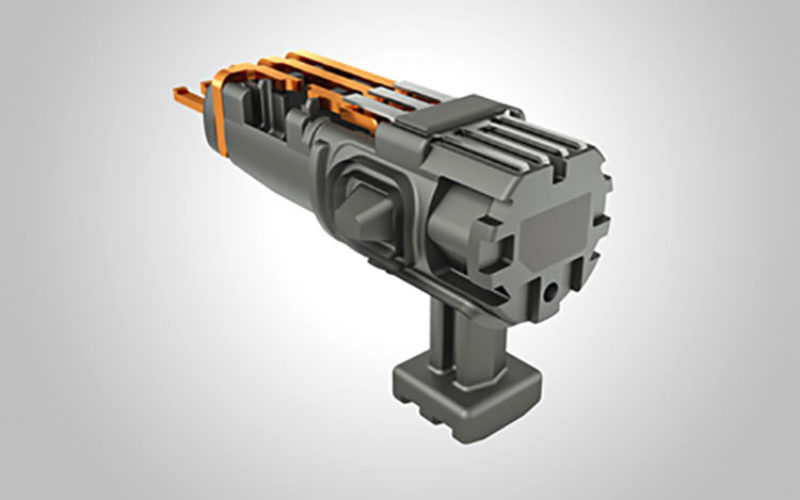

- MUSE integrates three different sensor functionalities into one unified element.

After the start of production in January 2014 the ten millionth Multi-application Unified Sensor Element (MUSE) was already manufactured and delivered to different customers worldwide. The assembling takes place in locations in China, Korea, India, Hungary, Brazil and Mexico. The MUSE is targeted for active camshaft and crankshaft position and speed sensors as well as transmission speed sensors. “Throughout the automotive industry, the cost of sensor elements is driven largely by volume. Combining different applications into one design maximizes the economies of scale”, said Thomas Jauch, Head of the Speed Sensors segment within Continental’s Passive Safety & Sensorics business unit.

The “true power on” (TPO), twist insensitive camshaft position sensor brings high accuracy and signal repeatability. It is highly reactive at start up and it has superior run out immunity. It can also operate without using rare earth magnet material. The crankshaft sensor can be programmed with or without direction detection within the same sensor design. It supports diverse pulse width protocols, and brings superior robustness to target wheel oscillations and temperature changes during engine stop and start phases. The transmission speed sensor features active diagnosis and vibration suppression. With high-speed sensing capability, it has several pulse widths available for direction detection.

Due to the high level of design and manufacturing concept standardization, MUSE greatly reduces the time and investment for development and validation testing, resulting in substantial development cost savings. The time to market Continental can offer to OEMs can be halved or more than halved when fully utilizing all the benefits the product provides.

Furthermore, end-of-line programming allows the MUSE to be highly optimized for any type of engine requirement. “By integrating a number of applications into a single sensor, the MUSE provides high flexibility to accommodate specification changes and engine evolution”, said Olivier Marle, Head of Electronics & Magnetics for Engine Speed Sensors, and Senior Expert Magnetic Sensors. “The integration of all engine and transmission speed sensors functionalities into one unique sensing element was a big challenge and after two years and ten millions parts produced the team can be proud of this achievement”, said Michael Le Bian, Head of Research & Development for Engine and Transmission Speed sensors.

In 2015 Continental’s Passive Safety & Sensorics business unit won the Automotive News PACE (Premier Automotive Suppliers’ Contribution to Excellence) Award for its innovative MUSE.