Schaeffler Drive Train 4.0: The next step in the digitalization of mechanical engineering

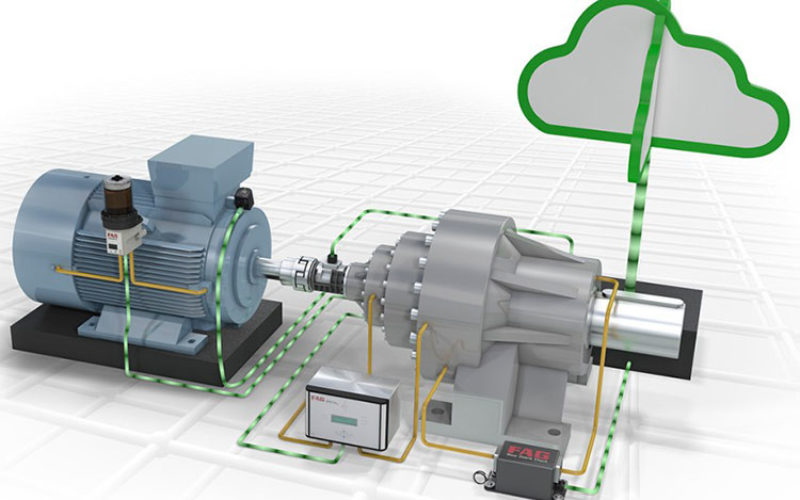

At the 2016 Hannover Messe, Schaeffler will be presenting a concept vehicle specifically for industrial drives with its Drive Train 4.0. The purpose of the exhibit is to demonstrate two newly-developed micro services, which focus on optimum machine capacity, longer machine operating times, data-based predictive maintenance, and reduced overall operating costs. The new micro services include the calculation of rolling bearings’ nominal remaining useful life during operation based on real load spectra, and automated rolling bearing diagnostics with the FAG SmartCheck vibration analysis system. Both services require a connection to the Schaeffler cloud as this is where the corresponding big data and software solutions are implemented. Software installations on the end devices of customers are not required, an internet browser and a network connection are sufficient.

The technology exhibit comprises an engine, clutch, and transmission and is designed to represent a wide range of drives in all performance classes. The latest generation of the FAG SmartCheck single-channel vibration analysis system, the FAG DTECT X1s multi-channel vibration analysis system, the FAG Concept2 automatic lubricator, the FAG WearDebrisCheck – an oil particle meter – and the FAG Xeleris torque measurement module are integrated into the drive. An outstanding characteristic of the innovative torque measurement module is that the sensor system does not affect the torsion rigidity of the drive train as the mechanical properties of the drive shaft are not affected. The dynamic behavior of the drive remains unchanged.

Schaeffler development engineers will be presenting the technical and commercial progress that can be realized with the respective products at the Hannover Messe trade show in Hall 17, booth A37.